Roll-center

The roll center is a theoretical point that is set by the suspension design and is (for our purposes) the point at which the chassis “rolls” around the suspension. Every suspension design has a different way to calculate this point (those points will be discussed later). The relationship between the roll-center and the COG (center of gravity) is called a roll-moment and it is what causes a vehicle to roll more and less in corners depending on the length of the roll-moment. The further the center of gravity is above the roll-center the more the vehicle will lean while cornering and the closer the COG is to the roll-center, the less the vehicle will lean – despite popular belief, this is why if you lower a vehicle it will typically not lean as much in corners, not because it’s closer to the ground, but because the center of gravity is closer to the roll-center (a vehicle does not know how far it is off the ground until it actually hits the ground). As long as the center of gravity is above the roll-center then the vehicle will lean to the outside of a corner (as we are all used to) and the further above the roll-center the center of gravity is the more lean you will get. If you were to modify the suspension in such a way to lower the roll-center without changing the height of the vehicle, the vehicle will lean more in corners than if you were to raise the roll-center. This isn’t always bad if you know what you’re doing as lower roll-centers are desirable for cornering traction and weight transfer, but extremely low roll-centers are not advantageous. Also, suspension designs that cause erratic roll-center movements should be avoided -a roll-center that moves around erratically can make the vehicle feel uneasy in corners and should be avoided on a daily driver.

To make a simple demonstration of what a roll-center is, here is a picture of the front suspension of a tractor. Sure it doesn’t have any springs or shocks, and it is only capable of articulating from side-to-side, but finding the roll-center doesn’t get much clearer than this.

The single point where the front axle is attached to the frame is, in this case, the front suspension’s roll-center. The chassis is forced to rotate around that single point on the axle as the vehicle drives over rough terrain. This is an over-simplified explanation, but the point is to show that roll-centers do, in fact, exist, and that more complex suspension designs require more complex means of finding the roll-center.

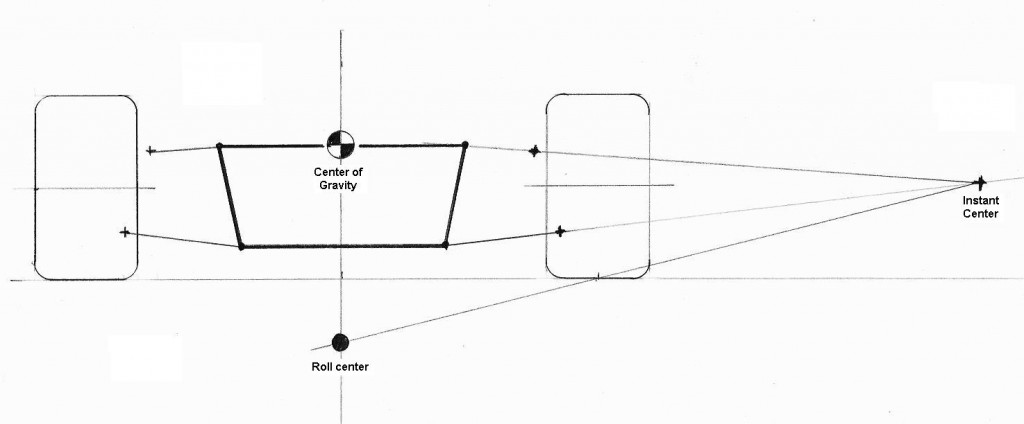

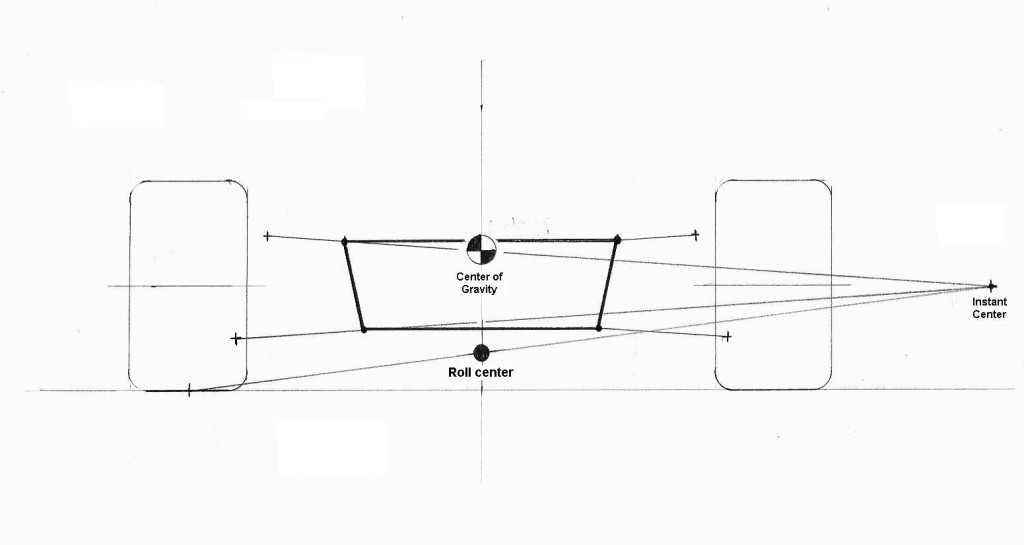

Showing a few of the more complicated suspension designs, here we have dual A-arm suspensions – the top one is a poorly designed system (common to suspensions where the upper arm mounts on the frame have been raised to help eliminate camber issues when laying on a tall tire) and the bottom one is a properly designed system. Notice in these diagrams that the COG is in the same place, but the poorly designed suspension has a much lower roll-center than the properly designed suspension.

Max you do an amazing job explaining suspension design/geometry for the people that don’t quite understand everything! I still have your article about front suspensions hanging on my wall and laminated! It has definitely helped out of lot throughout the years! Keep it up sir! I wish they had a suspension geometry class when I was in school!

Is there a certain length the instant center needs to be? Pros or cons of having one too short/long?